FIBERGLASS (GRP/FRP) SMC WATER TANK

Fiberglass Reinforced Plastic (FRP) or Glass Reinforced Plastic (GRP) water tanks, commonly manufactured using Sheet Molding Compound (SMC) technology, are a modern solution for water storage. These tanks are widely used in both residential and commercial applications due to their durability, corrosion resistance, and lightweight structure.

SMC water tanks are made from a composite of fiberglass and thermosetting resins, which provides superior strength and weather resistance compared to traditional steel or concrete tanks. The modular design of these tanks allows for easy assembly and installation, making them a popular choice in locations with space or logistical constraints. Additionally, they are non-toxic and safe for storing potable water, making them ideal for domestic, industrial, and municipal water storage needs.

Key benefits of GRP/FRP SMC water tanks include their long lifespan, resistance to rust, UV stability, and low maintenance requirements. Whether for rainwater harvesting, emergency water storage, or routine usage, these tanks offer an efficient and sustainable option for water management.

Technical Data

Material

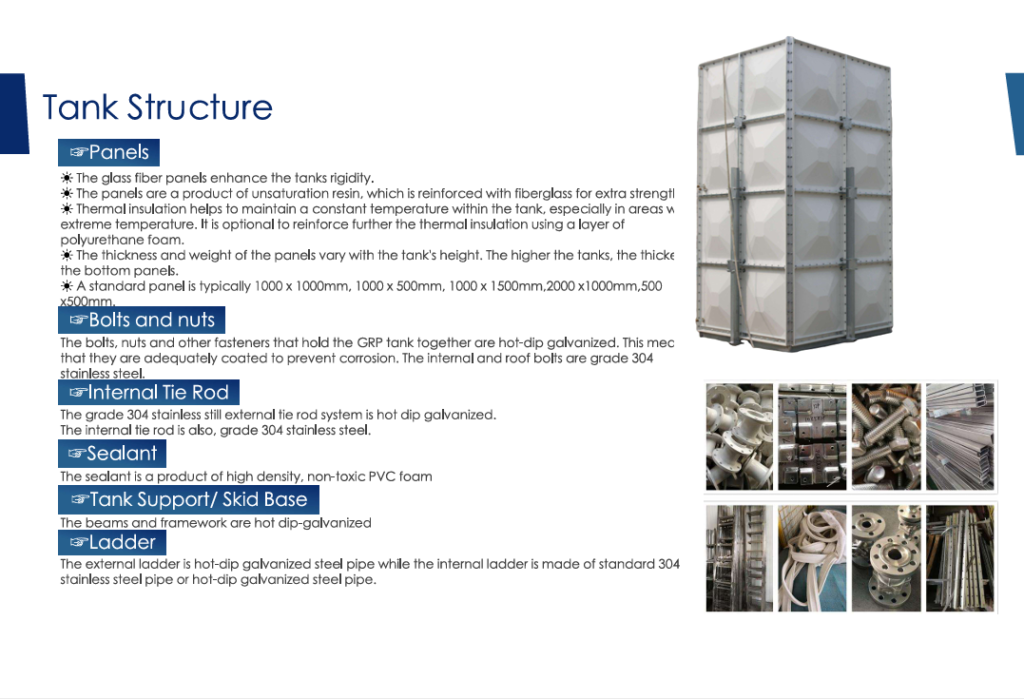

- Food grade unsaturated polyester resin.

- Alkali free twist glass roving

- Thickener (MgO), initiator curing agent, cross linking agent, UV inhibitor, etc.

Standard

Singapore Standard SS245: 2014 Equivalent to British Standard BS 7491 Part 3:1994 and BS EN 13280:2001

Size & Weight

- The size of FRP / GRP panels are produced by standard mould, having sizes of 1m*1m, 1m*0.5m, 0.5m*0.5m, 2m*1m, 2m*0.5m, 1.5m*1m, etc.

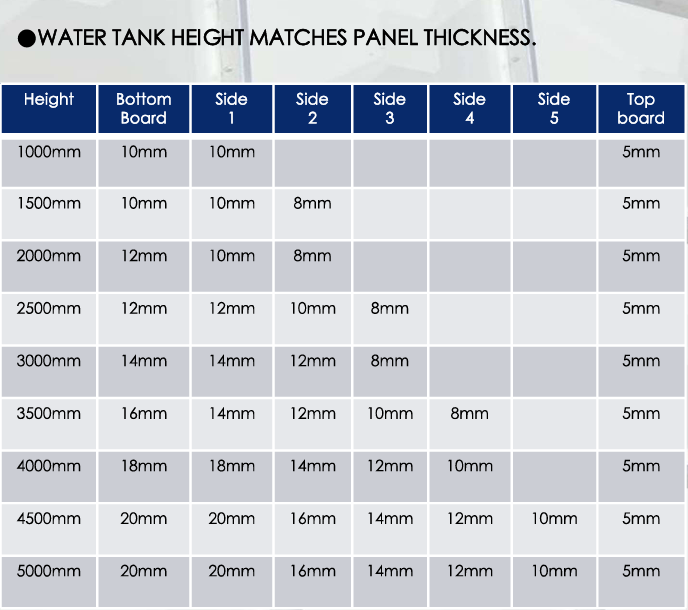

- Thank panel tickness depends on the height of the tank.

- The highest available height is 5 meters(C-channel or I-Beams external reinforcement are recommended for tanks heights 4 & 5 meters

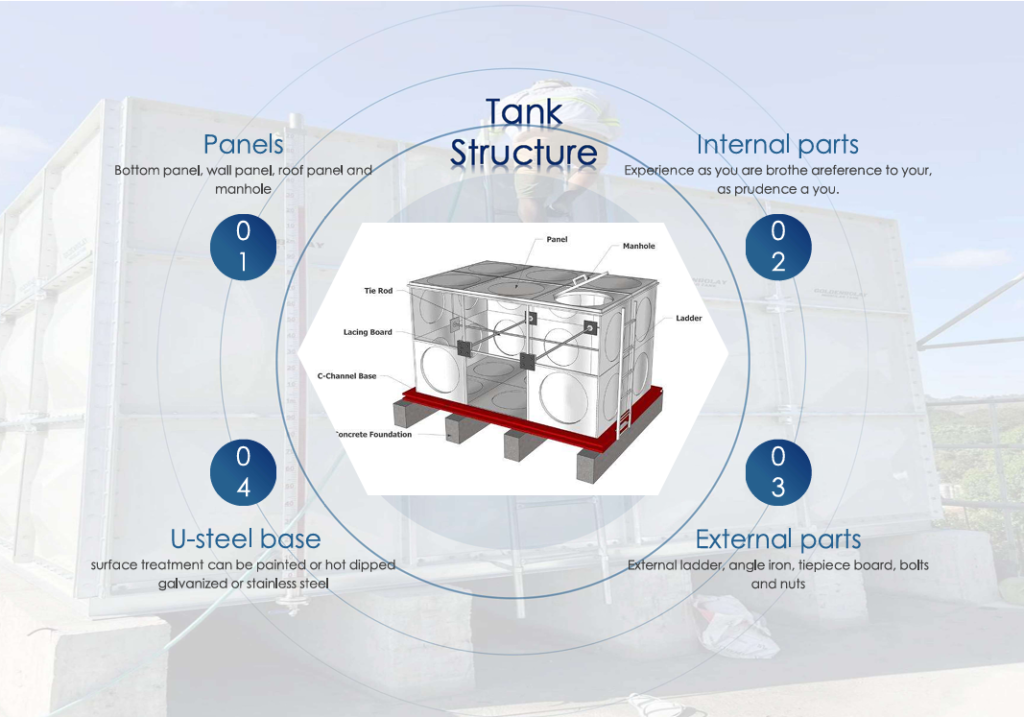

- Tank can either have Internal or external bracings and in some special cases, both.